Laser Applications

A multitude of laser marking and laser engraving applications

This versatile technology finds its place in a host of industries and applications. From automotive and aerospace to electronics and medical devices, laser marking and engraving offer unmatched precision and durability for the manufacturing, electronics, and medical fields to name a few.

Part Identification / Traceability

Traceability is the ability to identify all variables that go into the production and use of an item; from procurement of raw materials, to details of production and distribution, to eventual consumption and disposal. The purpose of product traceability is to clarify “how, when and where the product was produced, and how, when and where the product was consumed,.” Due to improving product quality and the rise in safety awareness in recent years, traceability has been increasing in importance and spreading into a wide range of fields, such as automotive, electronics, food and pharmaceutical. The permanence and flexibility of laser marking is ideally suited to accomplishing the goals of traceability. If your material can be laser marked, it can be traced using the latest technology.

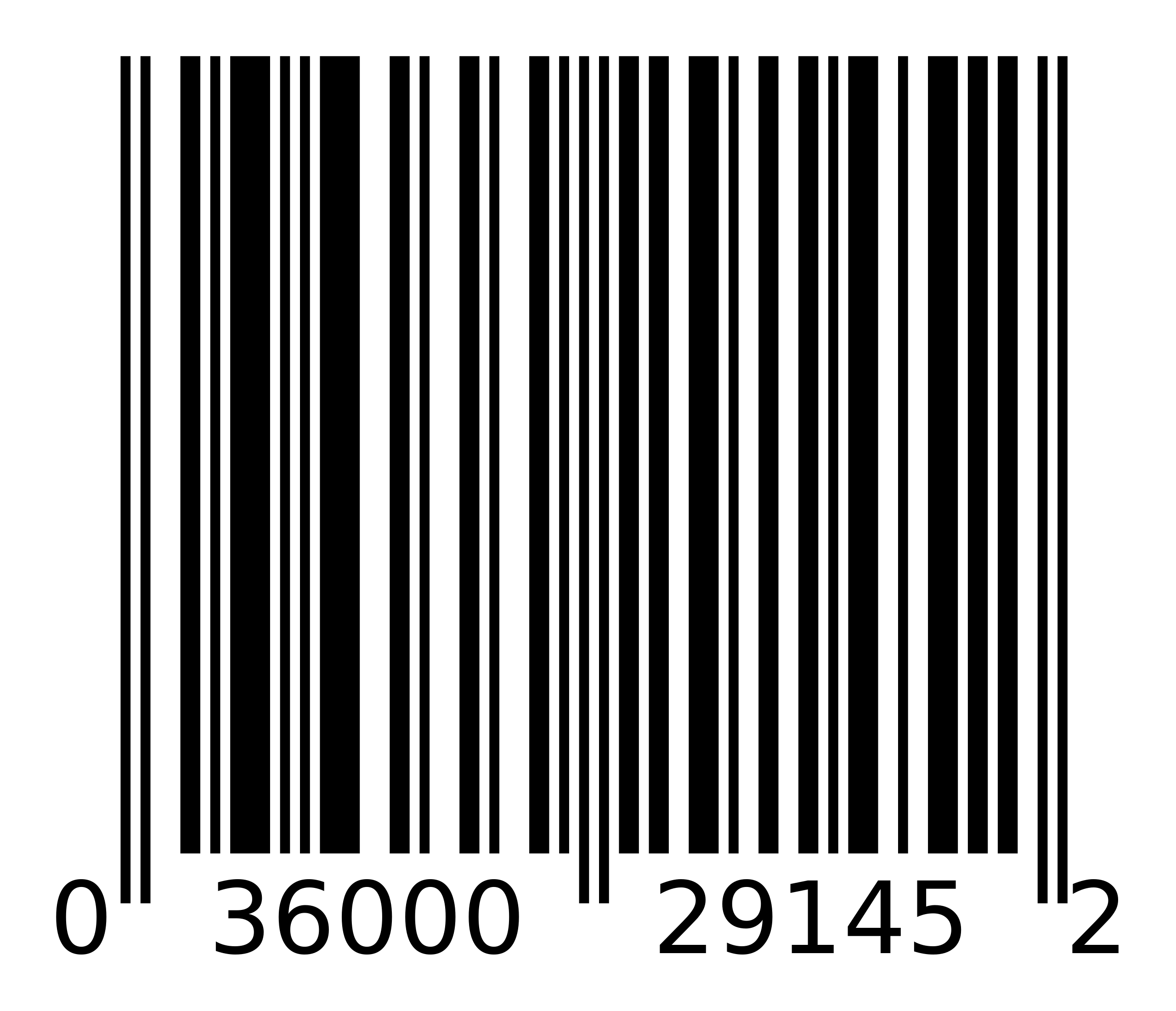

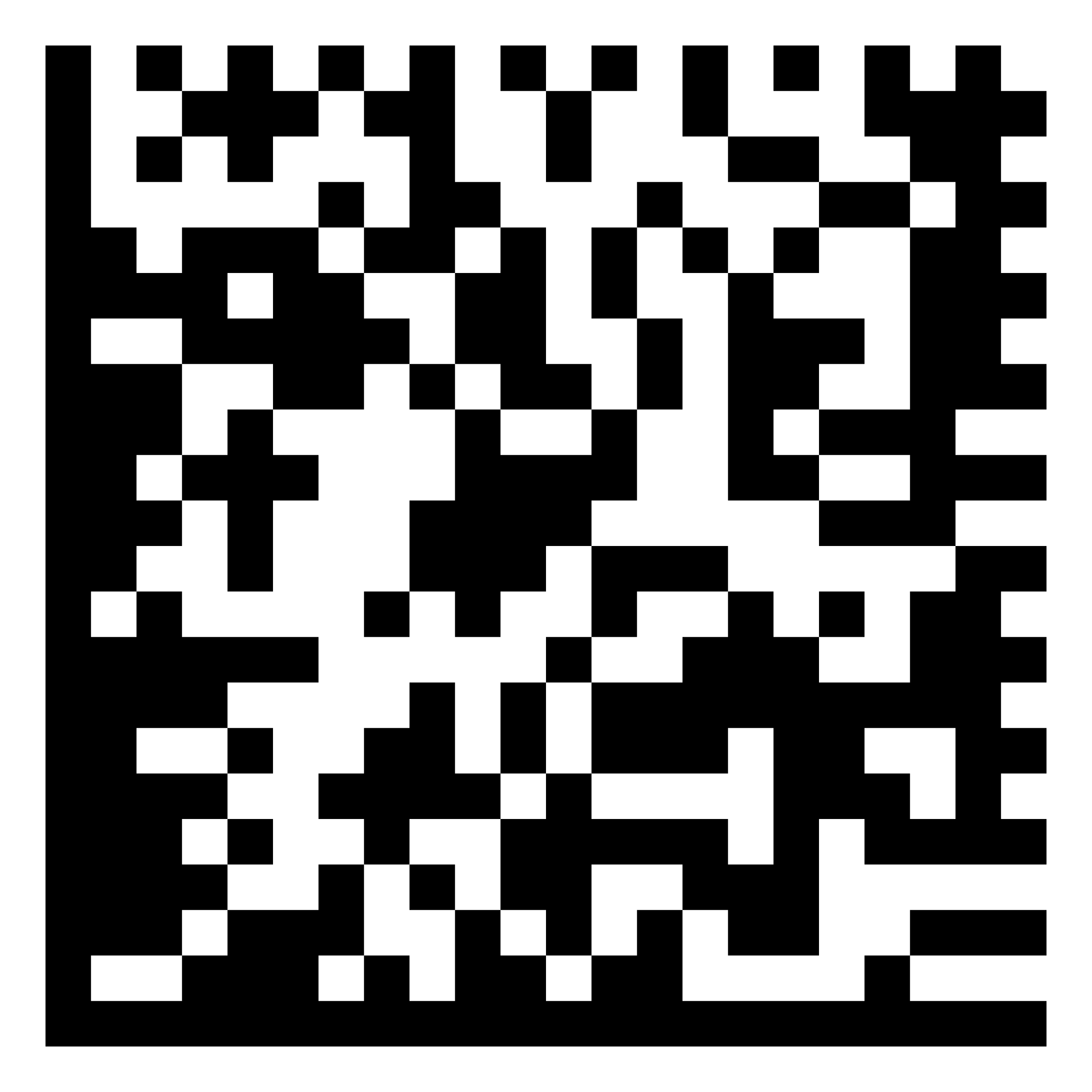

Part identification and traceability are accomplished by manufacturers using part numbers, serial numbers, heat lots, raw material lots, product expiration information, etc. Using traditional 1D barcodes or more modern 2D matrix codes allows manufacturers to include all of the traceable information of a product’s production, distribution, and use into a machine readable code that only takes up a small portion of the product’s surface area.

1D bar codes (traditional)

Entering use in the early 1970’s, 1D bar codes were originally used to identify products in commercial transactions such as retail purchases. Many people are familiar with this type of code from purchasing an item of clothing at a store, or a food product from a grocer. 1D bar codes can hold up to 80 alphanumeric characters.

2D matrix codes

Developed in 2004, 2D matrix code is a set of data printed as a square or rectangular symbol made up of individual dots or squares. This representation is an ordered grid of dark and light dots bordered by a finder pattern that can be read by an image based bar code reader or a mobile device capable of scanning codes. 2D matrix codes can contain up to 2,335 alphanumeric characters, can be read after maintaining 30% damage, and can fit in a limited area.

More Applications

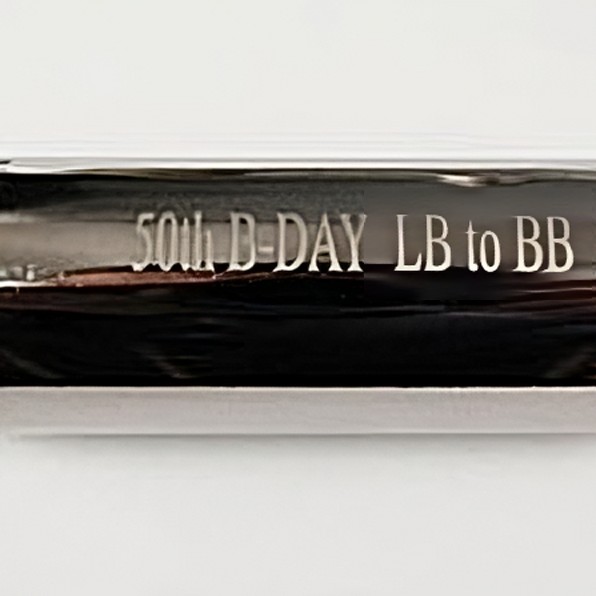

Besides traceability, laser marking and laser engraving remains an ideal method for accomplishing more traditional part marking needs. Laser marking is superior to older technologies such as stamping and punching, scribing, vibro peen, silk screening, acid etching, stickers, tags, and pad printing.